click for navigation

Specializing in :

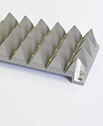

- Wire EDM Services

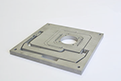

- Plunge (sinker) EDM Services

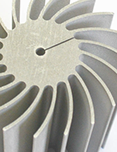

- Fine Hole EDM Services

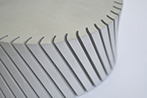

Swiss Wire E.D.M. specializes in complex prototype & production work for the aerospace, medical, & commercial industries, with a particular capability for machining large components. Our proprietary technology allows us to EDM parts as tall as 48", and workpieces weighing up to 4500 pounds.

By contrast, they have a number of production contracts involving parts that are small enough, almost to be considered microscopic, with corner radii less than 0.001.

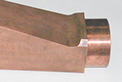

Many of the latest exotic alloys used in the aerospace industry such as titanium and molybdenum are much more easily machined with EDM than with conventional techniques. Their strong business partner relationships with approved CNC machining vendors provide your project with certified solutions that involve both conventional machining and EDM.

Their ISO 9001:2008, AS9100C, and NADCAP certifications make available mission critical services to manufacturers and engineers completing government, aerospace, and medical industry contracts unable to rely upon statements of "compliance to standards".

Since our founding in 1977, process, quality control, and innovation have always been paramount in our business' operations.

The operating staff of our company has a mandate from top management not only to stay on the leading edge of technology, but also to ensure that Swiss Wire EDM is the leader in our industry for both quality and customer satisfaction. The certifications listed below are proof of this commitment.

Swiss Wire E.D.M.'s QMS Program will ensure that you, as our customer will get the best quality products "on-time", "every-time". The QMS program is adhered to by all members of management & operating staff, and is 3rd party audited to maintain certifications.

As of March 7, 2017, Swiss Wire E.D.M. has been certified to the ISO9001:2008 without design and AS9100C standard. We are delighted to serve our customers even better through the well-defined and documented procedures this certification requires. While we’ve always been committed to quality in our products and services, this certification ensures a more productive environment through faster identification and resolution of quality issues, among many other benefits.

We partnered with Smithers Quality Assessments, www.smithersregistrar.com, an accredited quality and environmental management systems certification body, to achieve our certification.

ISO9001:2015 and AS9100C CERTIFIED

NADCAP CERTIFIED

SCOPE OF ACCREDITATION: Nonconventional Machining

ROLLS ROYCE CERTIFICATION

QUALIFIED VENDOR #221976

International Traffic in Arms Regulations Registered

PARKER-HANNIFIN CERTIFICATION

PARKER AEROSPACE VENDOR LINK

UNITED TECHNOLOGIES

PRATT & WHITNEY

COLLINS AEROSPACE

HAMILTON SUNDSTRAND

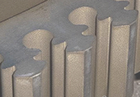

Responding to the exploding demand for close tolerance small hole features in aerospace, medical and other components, Makino has met the challenge with speed and innovation. This machine is capable of drilling fine holes as small as 0.004” (0.10mm) in diameter into any electrically conductive material with great speed and accuracy, with only certain depth/diameter ratio limitations. (Even smaller holes can be drilled on a custom basis.) The quality of these holes is outstanding. Size control is typically within 0.0005” (0.012mm) and finishes are smooth and burr-free. Hole patterns can be programmed to generate any practical layout, from single holes to an array of thousands.

AEROSPACE INDUSTRIES - We have a dedicated fine hole department specializing in fabrication of rocket engine/thruster injection plates. Capabilities include hole sizes down to .0040’’ diameter as well as micro window shapes. (5) axis equipment so all angles are achievable. We have achieved process capabilities resulting in centerline impingement less than .0005’’ with 100% atomization.

Swiss Wire EDM has both wire and ram type EDM capabilities. Our facility is conveniently located to service the entire country. We offer fax and email transmission for immediate response to your manufacturing requirements, as well as 24-hour delivery to anywhere in the USA. Utilizing a programming and retention system responsive to all forms of data transmission and a climate controlled shop, we are able to ensure repeatability and consistent duplication of dimensions.

QTY. MACHINE TYPE MACHINING CAPACITY

31" x 23" x 32.2" Z

12.5" x 9.5" x 8.5"

24" x 16" x 16" Z

15" x 11" x 8.5" Z

20" x 30" x 24" Z

10" x 16" x 10" Z

20" x 40" x 24" Z

16" x 30" x 14" Z

10" x 12" x 12" Z

14" x 19" x 48" Z

14" x 19" x 30" Z

WIRE EDM

(1) Mitsubishi MV 4800

(1) Mitsubishi BA8

(1) Mitsubishi BA24

(1) Mitsubishi NA1200

(1) Mitsubishi FA30

(1) Agiecut 250HSS

(1) Mitsubishi 300HA

(1) Mitsubishi 200HA

(2) Mitsubishi 90HA

(1) Mitsubishi FX20

(2) Mitsubishi FX20K

NOTE: The above dimensions in no way limit our capabilities. We can construct tooling to machine other components of larger and more complex shapes.

QTY. MACHINE TYPE MACHINING CAPACITY

43" x 29" x 14.5" Z

12" x 10" x 10" Z

11.8" x 9.8" x 9.8"

31.5" x 11.8" x 8.7"

RAM EDM

1) Agie Advance

(1) Makino Edge 2

Plus Fine hole

(1) Mitsubishi EA-8

(1) Makino EDNC-8

QTY. MACHINE TYPE MACHINING CAPACITY

SMALL HOLE EDM

(1) Current CT500F, Small Hole EDM .004" to .125" dia. holes

(1) Makino Edge 2 12" x 10" x 10" Z

(2) Makino EDAF (5 axis) 17.7" x 13.8" x 13.8"

(1) Gromax SD-43 15" x 11" x 13.5"

QTY. MACHINE TYPE

(1) Mitutoyo Vision QV Optical measuring device

(1) Faro Edge CMM Arm, 9 foot, 7 axis, with Verisurf software

(1) Microscope

(1) Video Comparator

(1) Mitutoyo CMM 9106T

SUPPORT EQUIPMENT

* Lathes

* Mills

* Grinders

* Bead Blaster

* Welder

* Saws

Complete conventional machining & bench facilities.

Responding to the exploding demand for close tolerance small hole features in aerospace, medical and other components, Makino has met the challenge with speed and innovation. This machine is capable of drilling fine holes as small as 0.004” (0.10mm) in diameter into any electrically conductive material with great speed and accuracy, with only certain depth/diameter ratio limitations. (Even smaller holes can be drilled on a custom basis.) The quality of these holes is outstanding. Size control is typically within 0.0005” (0.012mm) and finishes are smooth and burr-free. Hole patterns can be programmed to generate any practical layout, from single holes to an array of thousands.

SWISS WIRE E.D.M.

3505 Cadillac Ave. Unit J-1

Costa Mesa, CA 92626

877-467-9336

fax 714-557-2959

All Rights Reserved © Copyright 2024